Inexpensive Lift Repair Near Me: Professional Service Technicians at Your Service

Inexpensive Lift Repair Near Me: Professional Service Technicians at Your Service

Blog Article

Diving Into the World of Lifts: Typical Problems Faced by Different Lift Devices

As we navigate through the upright transport systems of contemporary buildings, elevators stick out as an important component of our every day lives. However, behind their smooth operation exists a globe of elaborate devices that can sometimes come across difficulties. From hydraulic elevators to traction systems and machine-room-less styles, each lift kind includes its collection of usual problems. Recognizing these challenges is vital for ensuring the smooth functioning of these crucial systems. Allow's check out the complexities that underlie the operation of lifts and the potential problems that can develop, losing light on the intricate web of lift mechanisms.

Hydraulic Lifts

Hydraulic elevators, typically liked for low-rise structures, make use of fluid pressure to control the movement of the elevator auto (lift repair companies). This mechanism includes a hydraulic pump pushing oil into a cylinder, triggering the lift to relocate the wanted direction. While hydraulic elevators are known for their silent and smooth procedure, they do feature their very own collection of typical problems

One prevalent problem with hydraulic lifts is oil leakage. In addition, concerns with the control system, such as malfunctioning shutoffs or a malfunctioning pump, can trigger interruptions in the elevator's activity.

Normal maintenance and prompt repairs are important to guarantee the smooth performance of hydraulic lifts. By dealing with these common concerns proactively, building owners can decrease downtime and make sure the safety and security and effectiveness of their vertical transport system.

Grip Elevators

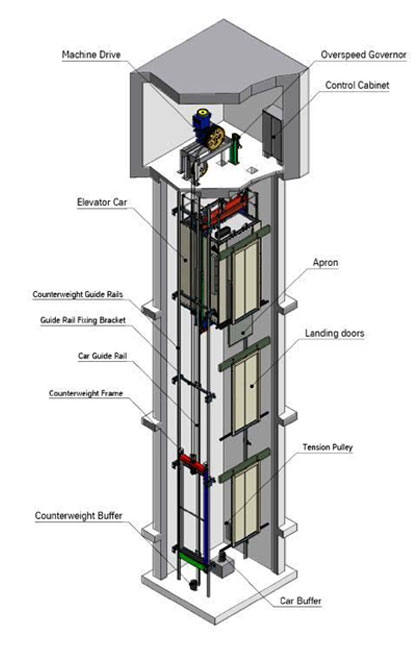

When considering vertical transport systems in buildings, another usual type in addition to hydraulic elevators is the grip elevator. Grip elevators run using a system of ropes and weights that move the elevator vehicle by clutching onto the hoist ropes. This mechanism permits smoother and quicker vertical transport compared to hydraulic systems.

One of the common problems faced by grip elevators is rope wear. The consistent motion of the ropes within the grip system can result in damage in time, possibly creating the elevator to malfunction or end up being unsafe for use. Normal evaluations and maintenance of the ropes are important to ensure the elevator's correct functioning and security.

An additional issue that traction elevators may come across is associated with the control system. Problems with the control system can cause problems such as erratic motion, hold-ups in reaction times, or even full shutdowns. Routine testing and upkeep of the control system are crucial to avoid such concerns and make certain the elevator's reliability.

Machine-Room-Less (MRL) Elevators

One of the vital parts of MRL lifts is the compact gearless traction maker that is installed within the hoistway. This machine efficiently drives the lift vehicle without the demand for large devices discovered in typical traction lifts. In addition, MRL lifts normally utilize a weight system to stabilize the automobile, further improving their power effectiveness.

Regardless of their advantages, MRL lifts may deal with difficulties associated with maintenance and repair service due to the confined area for devices installation. Availability for servicing parts within the shaft can be restricted, requiring specialized training for service technicians. Appropriate upkeep timetables and normal inspections are essential to make certain the ongoing smooth procedure of MRL elevators.

Overloading and Weight Limit Issues

Are elevators furnished to manage excess weight lots successfully and securely? Overloading and weight limit issues are vital worries in elevator procedures. Elevator manufacturers layout raises with particular weight abilities to make sure passenger safety and security and equipment durability. Surpassing these weight restrictions can cause different problems, consisting of mechanical failings, delays, and safety threats.

When lifts are overloaded, it places extreme stress on the motor, wires, and various other components, possibly creating failures or malfunctions. If they find excess weight, safety devices such as sensing units and overload sensors are in area to protect against elevators from relocating. Furthermore, exceeding weight restrictions can cause enhanced energy usage and wear and tear on the lift system.

To mitigate overloading issues, constructing managers must prominently show weight limitations in lifts and enlighten residents on the importance of adhering to these limitations - lift repair companies. Normal upkeep checks by certified technicians can additionally assist ensure that lifts are operating within safe weight specifications. By addressing overloading and weight limit issues proactively, building proprietors can improve elevator safety and security and performance

Electrical System Failings

Surpassing weight limits in elevators can not just bring about mechanical problems yet also possibly add to electrical system failures within the lift facilities. Electrical system failings are an important issue in lift procedure, as they can cause unforeseen closures, breakdowns, and even safety risks. One usual electric concern is the overheating of components due to excessive existing flow brought on by overwhelming the elevator beyond its capacity. This can cause harm to the electric motor, wiring, or control systems, resulting in costly repair work and downtime.

Furthermore, power surges or fluctuations in the electric supply can likewise interfere with the lift's operation, influencing its efficiency and security. These electric disruptions can damage sensitive lift elements such as control panels, circuit boards, or sensors, resulting in system failings. Normal upkeep and examinations are essential to recognize and resolve possible electric concerns immediately, guaranteeing the efficient and secure operation of elevator systems. By sticking to weight restrictions and carrying out routine electric system checks, structure owners can mitigate the threat of electrical failings in elevators.

Verdict

Hydraulic elevators, commonly preferred for low-rise buildings, use fluid pressure to manage the movement of the elevator vehicle.When thinking about vertical transportation systems in buildings, one more typical type aside from hydraulic elevators is the grip elevator. Grip elevators run using a system disabled platform lifts prices uk of ropes and counterweights that relocate the elevator car by clutching onto the hoist ropes. Unlike traditional lifts that need a different equipment space to house the tools, MRL elevators integrate most of the parts within the shaft, removing the requirement for a dedicated device space.In conclusion, lifts encounter common concerns such as hydraulic breakdowns, grip system failings, and electrical system issues.

Report this page